Vibratory Drying Machines

Vibratory Drying Machines

Back

Back

Vibratory Dryers are used to dry the parts after the surface finishing process. Round vibratory dryers are filled with natural materials in granule form.

KROMAŞ VIBRATORY DRYING MACHINES

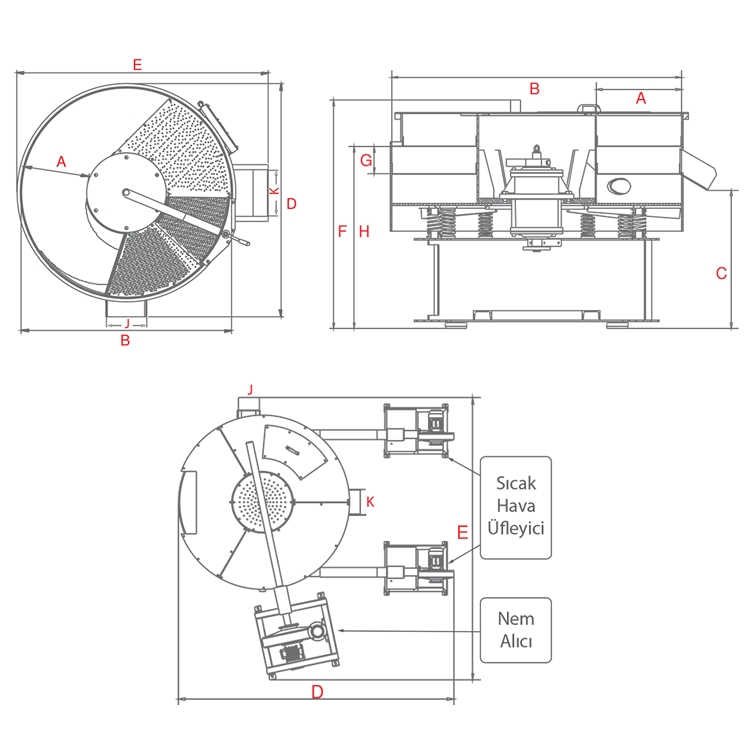

Vibratory Dryers are used to dry the parts after the surface finishing process. Round vibratory dryers are filled with natural materials in granule form. The wet parts are loaded continuously and dried with pre-heated granules in the process bowl.

All the moisture on the parts is absorbed by the granule and the parts are automatically sifted and discharged from the machine as 100 percent dried. Closed systems that provide drying in one round with extra hot air pressure and humidity control are produced optionally.

After the polishing processes, the drying process performed with granules provides a clearer appearance of the surface brightness. In addition, thanks to our layered drying machines, parts of various shapes and geometries that are likely to have granule compression problems are easily dried by hot air.

The process bowl can be divided into independent sections with separators. This feature is very useful when sensitive parts are desired to be treated without touching each other or when a different process material is used for a separate process in each section. Acoustic soundproofing covers are also produced optionally.

Through surface finishing machines are mostly used in the automotive, aerospace, natural stone and woodworking industries.

KROMAŞ VIBRATORY DRYING MACHINES

Vibratory Dryers are used to dry the parts after the surface finishing process. Round vibratory dryers are filled with natural materials in granule form. The wet parts are loaded continuously and dried with pre-heated granules in the process bowl.

All the moisture on the parts is absorbed by the granule and the parts are automatically sifted and discharged from the machine as 100 percent dried. Closed systems that provide drying in one round with extra hot air pressure and humidity control are produced optionally.

After the polishing processes, the drying process performed with granules provides a clearer appearance of the surface brightness. In addition, thanks to our layered drying machines, parts of various shapes and geometries that are likely to have granule compression problems are easily dried by hot air.

The process bowl can be divided into independent sections with separators. This feature is very useful when sensitive parts are desired to be treated without touching each other or when a different process material is used for a separate process in each section. Acoustic soundproofing covers are also produced optionally.

Through surface finishing machines are mostly used in the automotive, aerospace, natural stone and woodworking industries.