Through Vibratory Surface Finishing Machine

Through Vibratory Surface Finishing Machine

Back

Back

Through vibratory surface finishing machines are ideal for the surface finishing of heavy, large, long or sensitive parts in terms of unlimited application possibilities.

KROMAŞ THROUGH VIBRATORY SURFACE FINISHING MACHINES

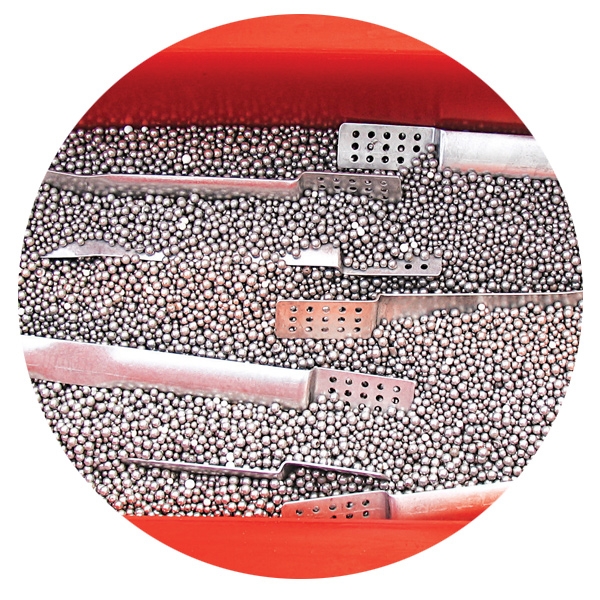

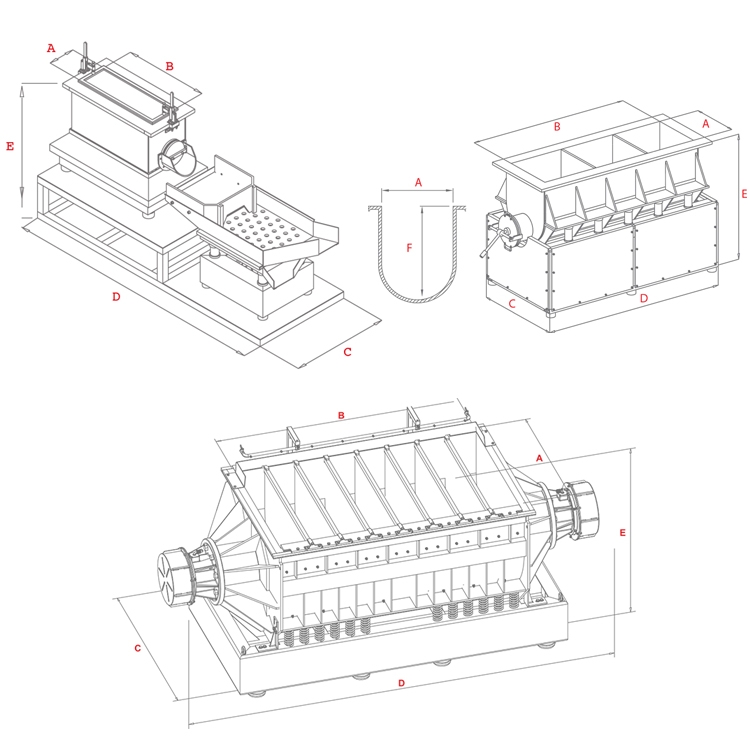

Through vibratory surface finishing machines are produced as standard in various sizes from 20 liters to 2200 liters. Special production is made for capacities above 2200 liters. As a standard, parts up to 2000 mm long can be grinded with plastic and ceramic abrasives in Through vibratory surface finishing machines, and polished with porcelain or stainless steel balls.

Through vibratory surface finishing machines are ideal for the surface finishing of heavy, large, long or sensitive parts in terms of unlimited application possibilities.

Drive motors are mounted under the machine, directly under the process bowl. In addition, larger capacity machines have two synchronous drive motors mounted on the sides of the bowl. Motors and weights are combined with unique vibration-absorbing couplings.

The process bowl can be adjusted or divided into independent sections with fixed separators. This feature is very useful when sensitive parts are desired to be treated without touching each other or when a different process material is used for a separate process in each section. Acoustic soundproofing covers are also produced optionally.

Through surface finishing machines are mostly used in the automotive, aerospace, natural stone and woodworking industries.

KROMAŞ THROUGH VIBRATORY SURFACE FINISHING MACHINES

Through vibratory surface finishing machines are produced as standard in various sizes from 20 liters to 2200 liters. Special production is made for capacities above 2200 liters. As a standard, parts up to 2000 mm long can be grinded with plastic and ceramic abrasives in Through vibratory surface finishing machines, and polished with porcelain or stainless steel balls.

Through vibratory surface finishing machines are ideal for the surface finishing of heavy, large, long or sensitive parts in terms of unlimited application possibilities.

Drive motors are mounted under the machine, directly under the process bowl. In addition, larger capacity machines have two synchronous drive motors mounted on the sides of the bowl. Motors and weights are combined with unique vibration-absorbing couplings.

The process bowl can be adjusted or divided into independent sections with fixed separators. This feature is very useful when sensitive parts are desired to be treated without touching each other or when a different process material is used for a separate process in each section. Acoustic soundproofing covers are also produced optionally.

Through surface finishing machines are mostly used in the automotive, aerospace, natural stone and woodworking industries.