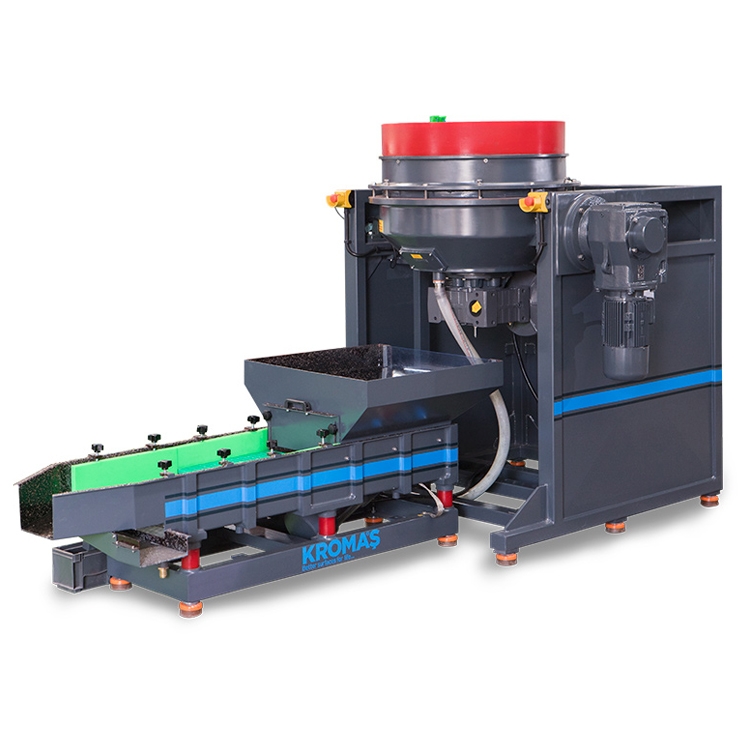

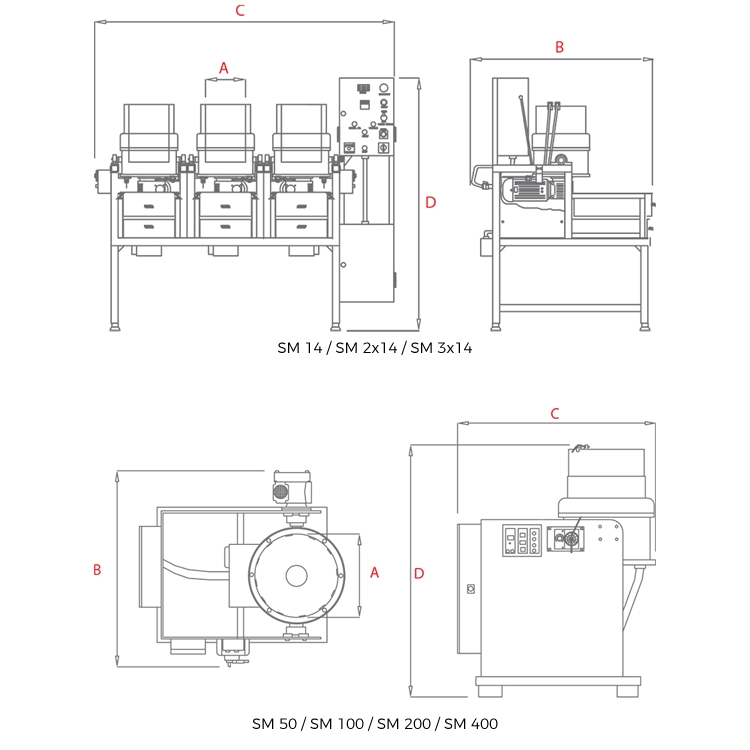

Centrifugal Surface Finishing Technologies 7 - 400 Litre

Centrifugal Surface Finishing Technologies 7 - 400 Litre

Back

Back

Kromas centrifugal surface finishing machines offer optimum solutions for high abrasion and polishing processes in small-sized parts with 10 times faster processing time compared to vibratory surface treatment machines.