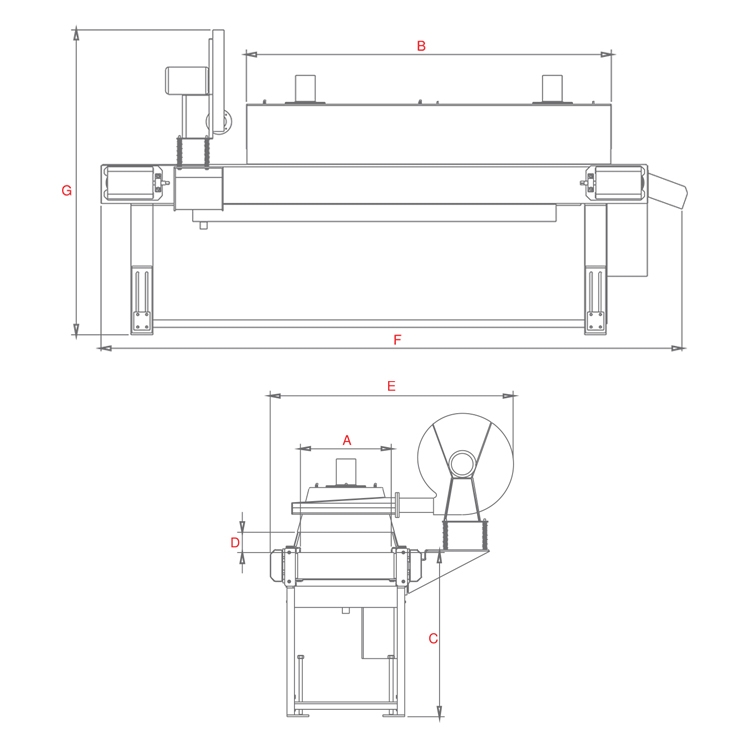

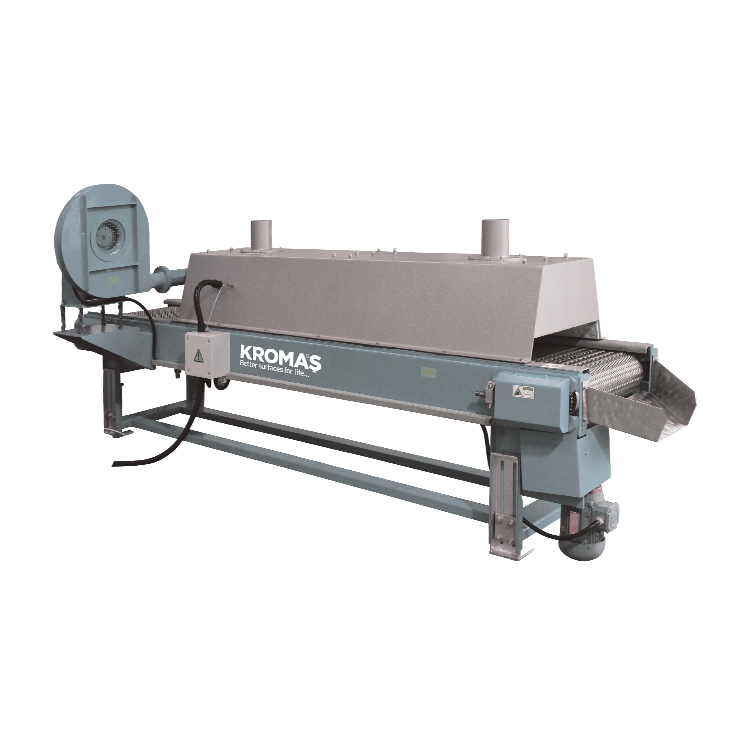

Belt Tunnel Drying Machines

Belt Tunnel Drying Machines

Back

Back

Kromaş Tunnel Drying machines are used for drying all small and large parts that are sensitive to impacts. Parts that cannot be vibrated due to their shape, size, weight or having too many holes on them, are ideal for this machine.

Drying takes place by means of the heating and hot air circulation inside the oven unit. Water sweeping air jets are produced as standard in all drying machines.

BELT TYPE TUNNEL DRYING MACHINES

Vibratory Drying machines are used for drying the parts after the surface finishing process. Round dryers are filled with natural materials in granule form. The wet parts are loaded continuously and dried with pre-heated granules in the process bowl.

All the moisture on the parts is absorbed by the granule and the parts are automatically sifted and discharged from the machine as 100 percent dried. Closed systems that provide drying in one round with extra hot air pressure and humidity control are produced optionally.

Drying takes place by means of the heating and hot air circulation inside the oven unit. Water sweeping air jets are produced as standard in all drying machines.

BELT TYPE TUNNEL DRYING MACHINES

Vibratory Drying machines are used for drying the parts after the surface finishing process. Round dryers are filled with natural materials in granule form. The wet parts are loaded continuously and dried with pre-heated granules in the process bowl.

All the moisture on the parts is absorbed by the granule and the parts are automatically sifted and discharged from the machine as 100 percent dried. Closed systems that provide drying in one round with extra hot air pressure and humidity control are produced optionally.