Automations 400 - 1200 Liter

Automations 400 - 1200 Liter

Back

Back

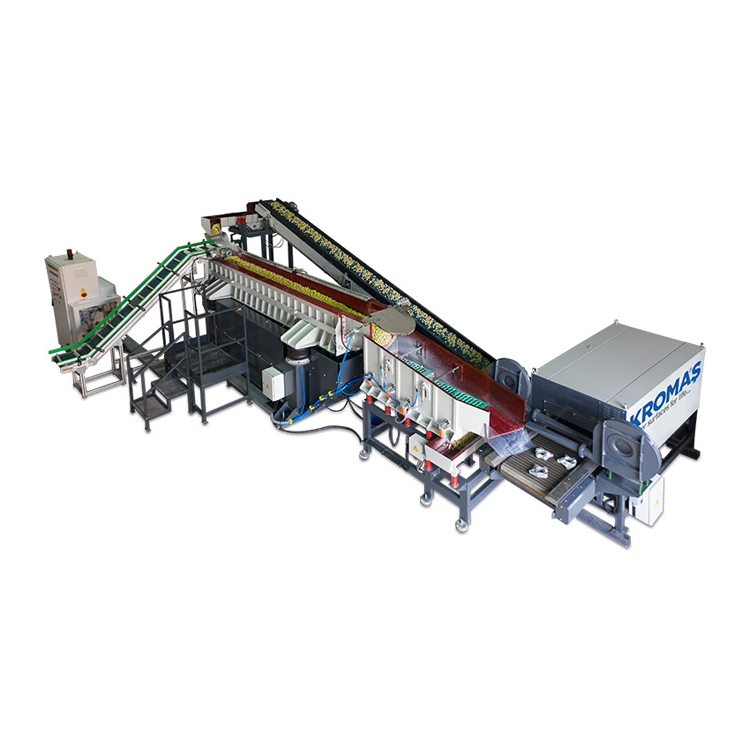

With the high capacity and efficient automation systems offered by Kromaş, all process steps are completed consecutively without human intervention. The processes (degreasing, deburring, polishing, etc.) are determined according to the part condition, and capacity and line systems are designed according to the number of parts to be processed.